Deciding on a total or partial overhaul of one's information system is a challenge for any company: as the saying goes, "we know where we're starting from, but we don't quite know where we'll end up". That's why IT directors embarking on this journey examine existing issues and call on IT professionals to support them throughout this process.

This was the case for our client; a French agri-food company specializing in the sale of frozen products that we supported in the restructuring of its information system. Our teams assisted this client in defining its integration strategy, in selecting solutions, and in the implementation of this project. A strategic challenge for this company that we approached with a methodical and proactive method.

This article describes the data flow architecture used to communicate Infor M3 ERP with Legacy via Boomi IPaaS.

I - Obsolete ERP project: challenges and action plan

1 - The main reasons for changing ERP systems

Faced with an increase in its activity, our customer has recently noticed slowness in the execution of its processes, and wishes to reinforce the safety and reliability of its ERP, which must constantly adapt to the latest safety standards.

The publisher of the former ERP has chosen to highlight its new version in Cloud mode, thereby reducing the level of support for the on-premise version. This will lead to several issues such as:

- A decrease in performance

- ERP obsolescence

- Absence of support and maintenance.

- Limited and non-upgradeable compatibility: an obsolete version is not compatible with new technologies and software versions, which can make it difficult to integrate new tools to meet new business needs or update existing processes.

- Lack of scalability

- Security vulnerabilities: an outdated ERP may not comply with the latest security standards, which can increase the risks of data breaches or cyber attacks.

To avoid these problems, our customer initiated a project to overhaul its ERP system and optimize all the data flows around it.

2 – A surge in activities facing a penalizing lack of scalability

Growth implies new needs; in this case, those of our client revolve around managing volume, implementing BI to support logistics and order forecasts, ... Additionally, there are technical needs related to optimizing response times and the type of installation (on-premise).

The IT Director and the business management of our client must therefore face the challenge of evolving their IS so that the system can align with their new needs. This ultimately leads to the decision to replace their ERP with Infor M3, a good compromise as it is capable of meeting the shifting needs of the business and adapting easily to future developments.

II - INFOR M3, the right choice?

It is in this context and to address these issues that our client has opted for the ERP Infor M3, designed to meet the management needs of the entire company, including supply chain management, financial management, production management, and human resource management. The solution offers a multi-company, multinational platform that can be deployed on-premise (on-site) or in the Cloud, and is suitable for businesses of all sizes and sectors.

Moreover, the ERP is equipped with features allowing companies to quickly adapt to changes in their environment, in terms of trends, business models, and growth of their activities.

III - The benefits of INFOR M3 combined with the expertise of a successful integration with We Are Beebay * BOOMI

1. We Are Beebay defines the integration strategy of the newly chosen ERP (INFOR M3) and its interface with existing applications

By choosing Infor M3, our client simultaneously had to revise its integration strategy by opting for the leader in intelligent connectivity and automation; Boomi, a pioneering publisher of the IPaaS solution.

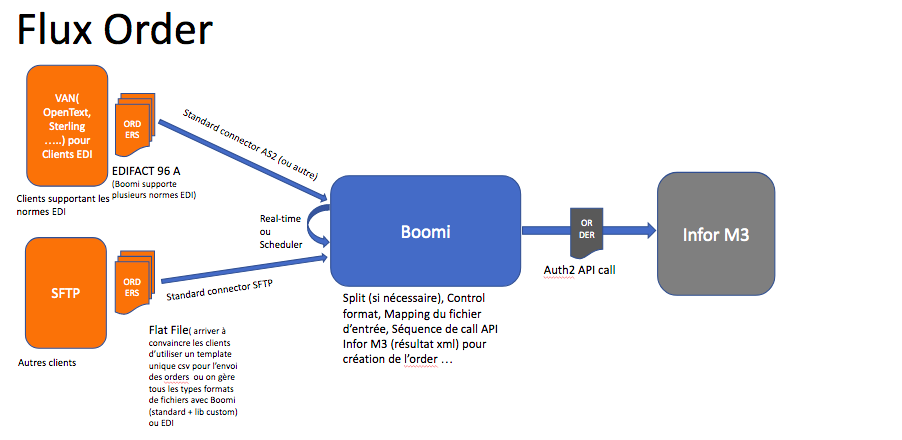

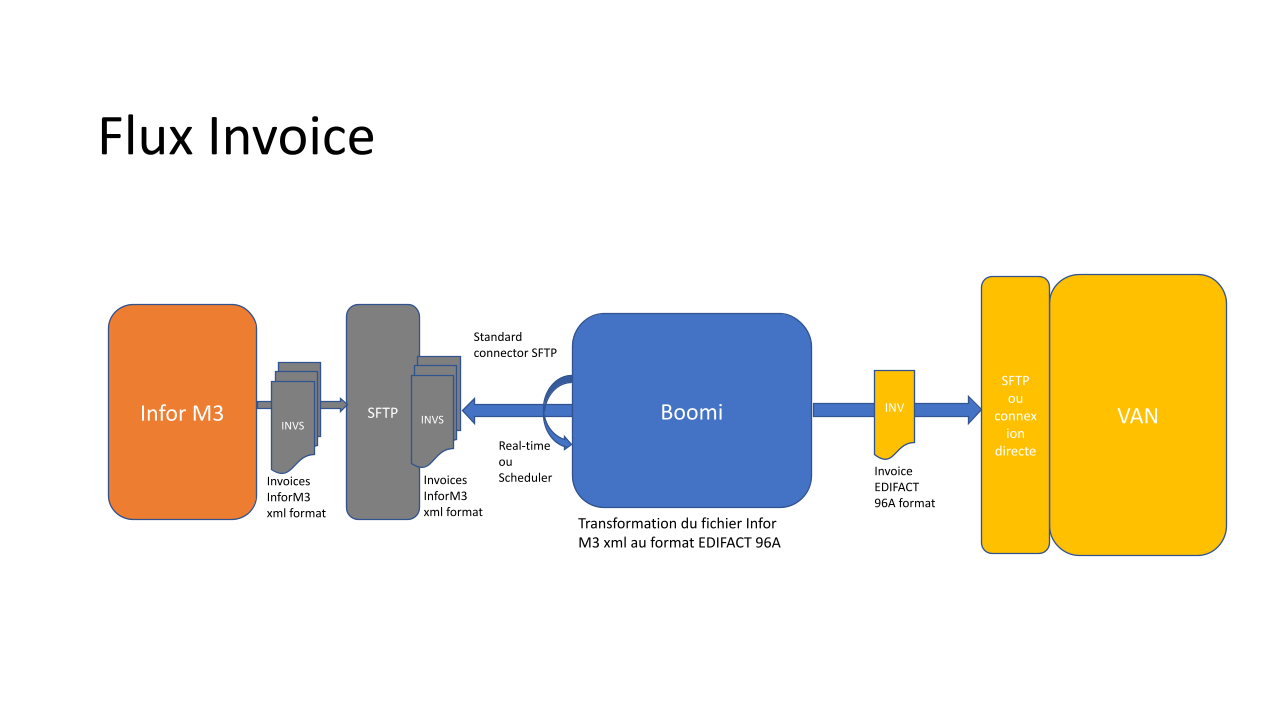

To do this, we supported them in initially connecting Infor M3 to the existing system: to communicate/interface with the VAN (Value-Added Network / various trading partners for EDI ORDER flows (orders), INVOICE (invoices), DESADV (shipping notices), INVRPT (inventory status)).

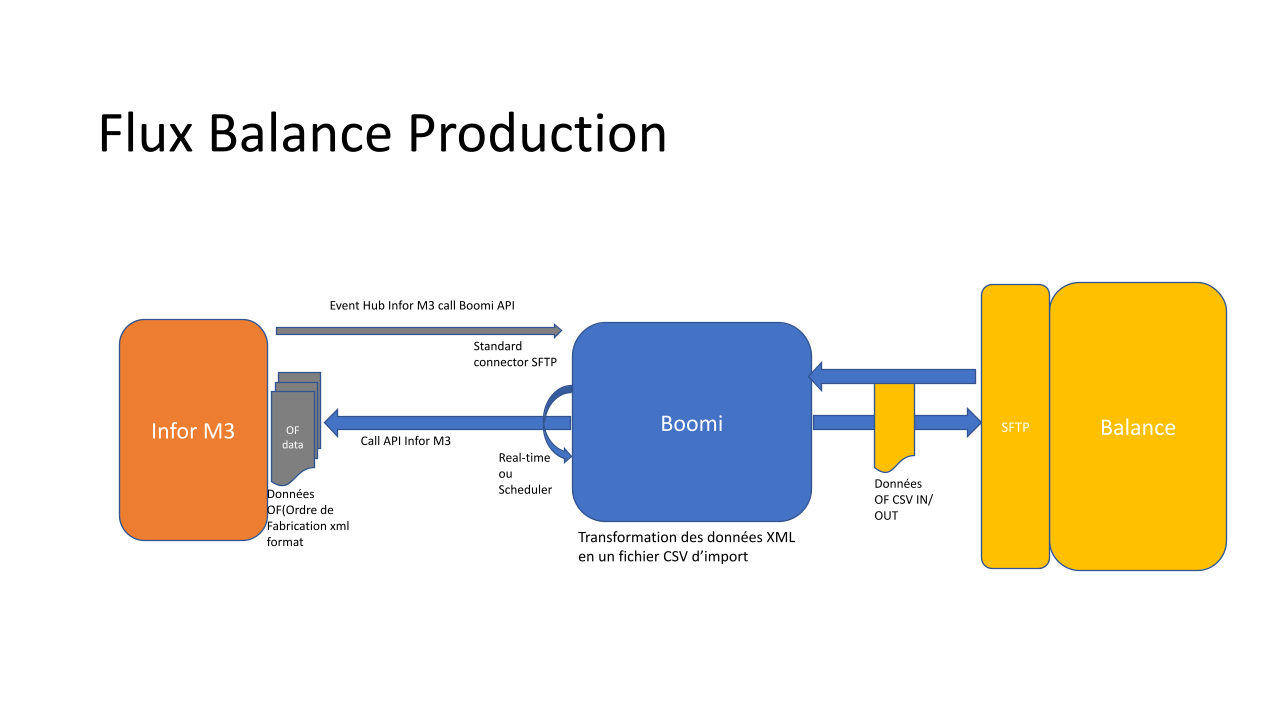

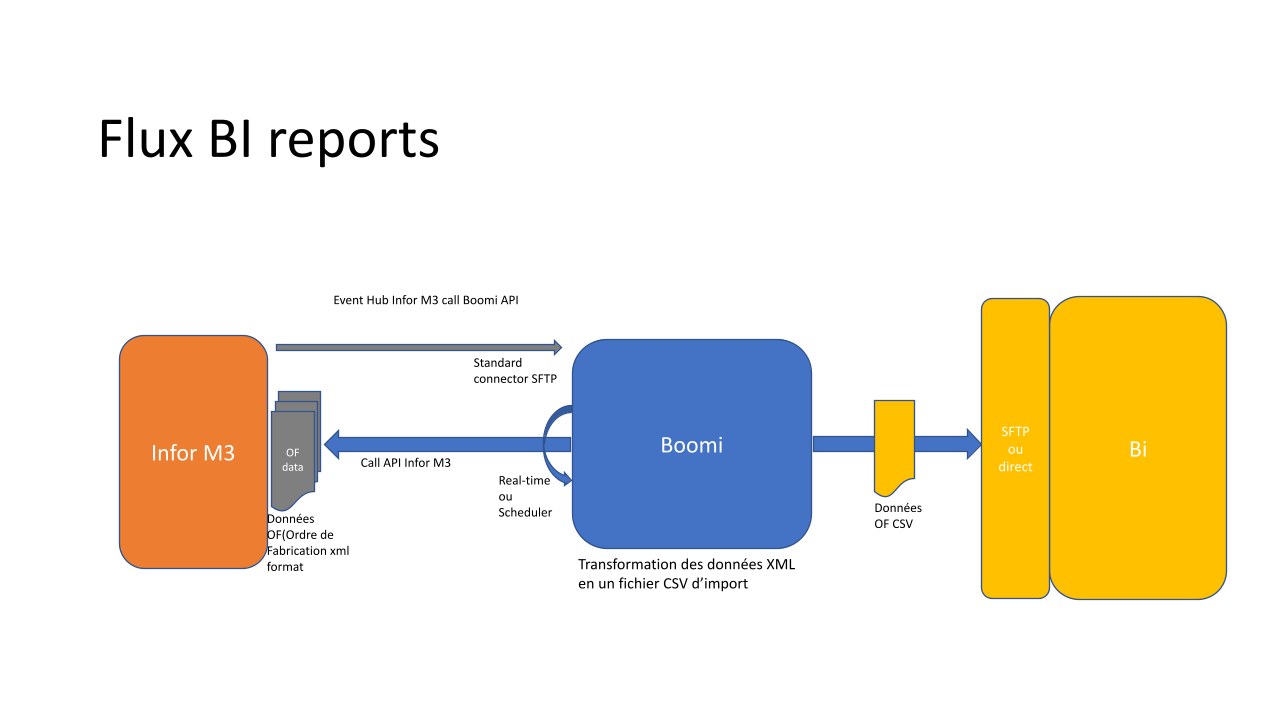

But also to create new flows to improve productivity (automation of the integration of the management of manufacturing orders (MO) interface of M3 with the scale) and to have a more complete view of the data through the implementation of a BI flow, which improves decision-making and the efficiency of the company.

2. Choosing Boomi IPaaS

Boomi natively offers a multitude of connectors that greatly facilitate the implementation of interfaces between different applications. For example, the integration of customer orders received in various formats, such as EDI, CSV, Fixed Format, Excel, or PDF.

Boomi can process data in real-time (Real-time event-driven execution) or schedule process executions (Scheduler). The platform natively manages different types of files (various EDI standards like EDIFACT 96A or flat file) and offers the possibility to import custom libraries to handle other types (Excel, PDF). It also allows for operations such as splitting, format checking, and transformation (mapping) of files (Example: from an EDI file to an XML file). Most importantly, Boomi can easily perform API Rest calls to Infor M3 by managing Auth2 authentication (with token refresh management), thus enabling the integration of order data. A similar Use Case applies for INVRTP (inventory status).

IV - Example of a Pattern

Use case 1: Order data integration

Use case 2: Sending invoices generated by InforM3

To send the invoices generated in xml format by Infor M3 to the customer via the VAN in EDI format, Boomi takes care of retrieving the invoices from the dedicated SFTP folder and transforming them into the correct EDI format, respecting the requirements/specifications of the end customer (specifications differ from one customer to another). Similar use case for DESADV (dispatch advice).

Use case 3: Automation of part of the production line: Scale interface (management of incoming/outgoing data flows OF (production order), recipe items ....)

Before automation, exchanges between the old ERP and the scale were conducted by exporting and printing daily the MOs (manufacturing orders) that needed to be processed that day by the manufacturing workshops using the scales. Similarly, in the reverse direction, at the end of each day, manual entry was made into the old ERP of data coming from the scale to reflect the day's work. Data also present/stored in the scale were manually programmed.

This flow thus allows communication between Infor M3 and the scale via Boomi and eliminates all human intervention (risk of error, productivity improvement).

Boomi is the right choice for this type of feed, as it natively handles xlm and CSV formats (read transformations, etc.).

Use case 4: combining / using Infor M3 data for BI purposes

The sharing of data from Infor M3 with BI tools enables clear and intuitive visualization, correlation with other data sources, and the creation of customized dashboards and reports to monitor company performance and identify improvement opportunities.

V- We Are Beebay support and the story of a company that dared to change

We therefore conclude that an ERP is primarily a solution that facilitates operations, performance, and customer/employee satisfaction. However, its implementation is often accompanied by major changes in a company's IS (Information System).

A project of IS overhaul smoothly conducted by our team of expert consultants, marking a new business turning point for our client. Enough to inspire you for the modernization of your IS!

Don't hesitate to contact us to learn more about what we can do for you.